Cavity Products

From 110m+150mm cavity lintels, to cavity closer and wall ties we have the products you need in stock!

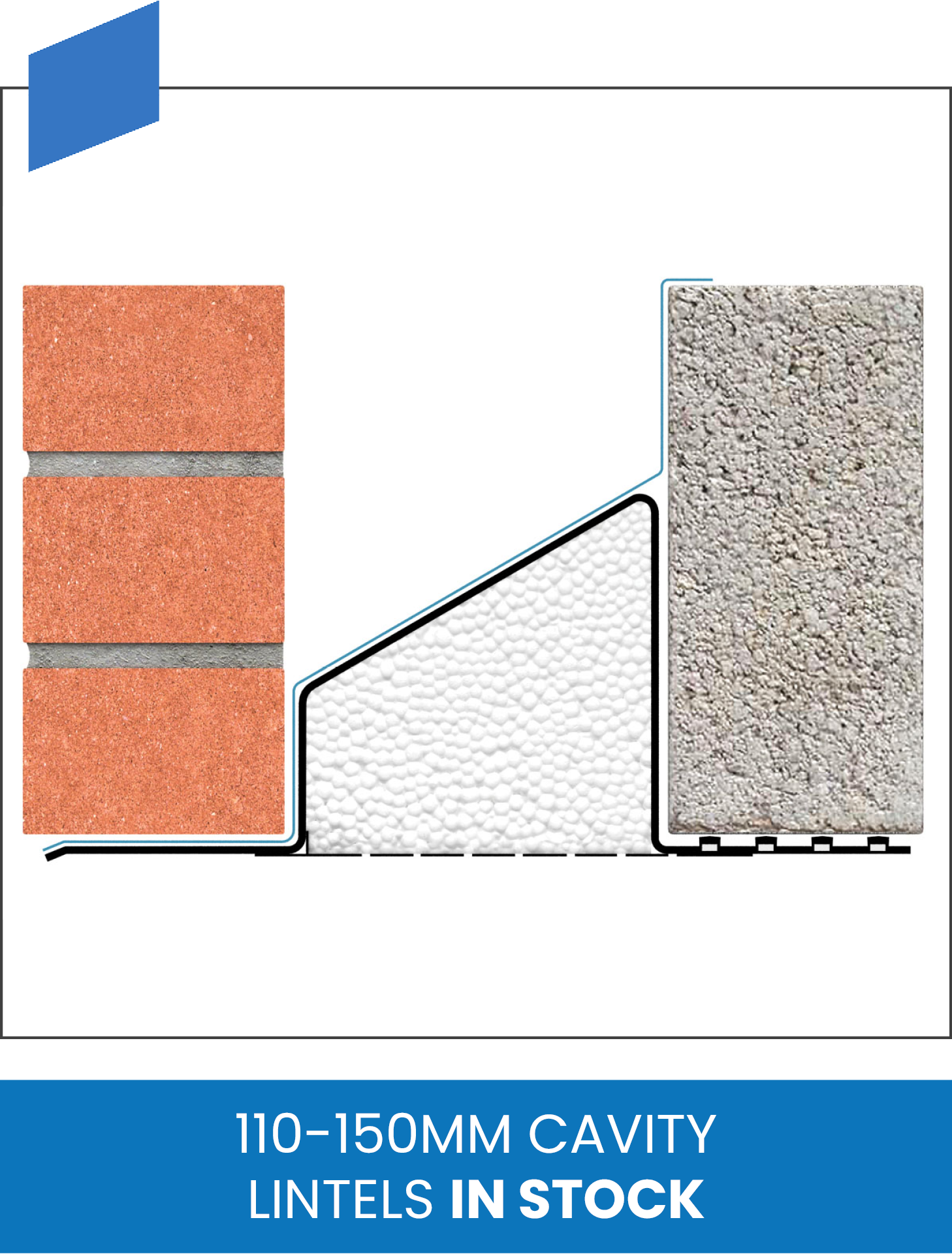

- 110-150mm cavity lintel

- 275mm wall ties type 4

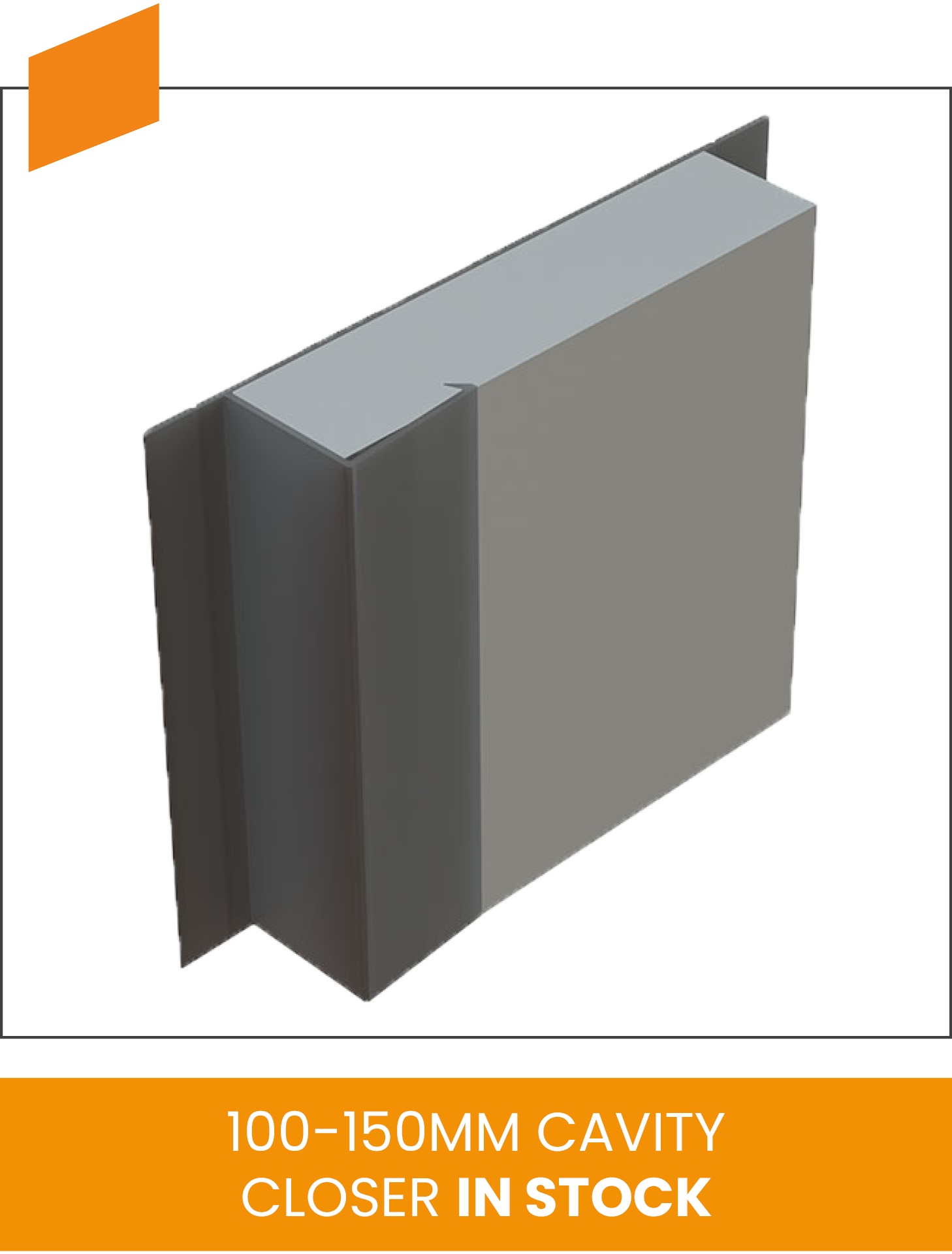

- 100-150mm cavity closer

- 600mm zedex DPC for wide cavity tray

Let us make it easy for you!

Send us your plans and we’ll do a lintel schedule from your drawings.

Email [email protected]

A cavity lintel is a structural component used in construction that is typically made of concrete or steel. It is used to support the load of the wall above an opening, such as a window or door, in a masonry wall. The cavity lintel is designed with a hollow centre to allow for the insertion of insulation material, which helps to reduce heat loss and increase energy efficiency. The cavity lintel is typically installed during the construction of the wall, with the lintel spanning the opening and resting on the adjacent walls or supports. The cavity lintel is then secured in place with mortar or other adhesive material.

Wall ties are metal components that are used to connect the two leaves (layers) of a cavity wall together. They are typically made of galvanized steel or stainless steel and are designed to prevent the two leaves of the wall from separating under loads such as wind or earthquakes. Wall ties are typically installed during the construction of a cavity wall, with the ties spanning the cavity and connecting the inner and outer leaves of the wall. The ties are spaced at regular intervals, typically every 600mm horizontally and every 450mm vertically, to provide sufficient structural support.

A cavity closer is a type of building component that is used to fill the gap between the inner and outer leaves of a cavity wall at openings such as doors and windows. It is designed to prevent the ingress of moisture, draughts, and pests, and to provide a thermal break between the two leaves of the wall to improve the energy efficiency of the building. Cavity closers are typically made of rigid foam insulation, which is encased in a uPVC or aluminium frame. The frame is designed to fit snugly between the inner and outer leaves of the wall, with the foam insulation filling the gap between the two leaves. This creates a continuous thermal barrier around the opening, which helps to reduce heat loss and improve the energy efficiency of the building.

A damp proof course (DPC) is a barrier that is installed in a building’s walls or floors to prevent moisture from rising through the structure. It is typically made of a waterproof material such as bituminous felt, plastic sheeting, or chemical compounds. Damp can cause significant damage to a building, including rotting of timber, deterioration of plaster, and the growth of mould and bacteria, which can be harmful to human health. A DPC is installed to prevent moisture from rising from the ground and entering the building through the walls or floors. Damp proof courses are typically installed at the base of a wall, above the level of the ground, or at a height of at least 150mm above external ground level. They can also be installed horizontally within walls, known as a horizontal DPC, or vertically between two leaves of a cavity wall, known as a cavity tray.